Drug production industries have always been among the most sensitive and necessary industries in the world and require special conditions for drug production. In this industry, it is important to use advanced and appropriate equipment and tools. One of these equipments is the ice bank device, which is used to maintain the quality and storage of pharmaceutical products. The ice bank device has become a smart choice for pharmaceutical industries. This article is designed to introduce the role of this device in the pharmaceutical industry.

Temperature in the pharmaceutical industry

Research centers, pharmacies, medical laboratories, hospitals, and other healthcare facilities often have very temperature-sensitive materials such as blood samples, drugs, vaccines, or pharmaceuticals that they use. These materials are often invaluable both to the scientists who use or study them and to the patients who may need them. In this way, specialists in these centers are responsible for organizing, transporting and maintaining these materials in a way that prevents damage or contamination.

This makes the ice bank device one of the most vital solutions for medical production in the pharmaceutical industry. Without a reliable cold storage solution, medical products can lose ingredients, face financial consequences, experience reduced productivity, and put the patients they serve at serious risk. This is why many labs and other facilities are turning to the Ice Bank for their cold storage needs.

What is an Ice Bank device?

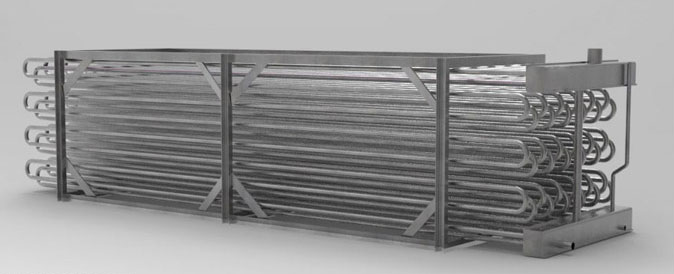

To fully understand the benefits of the Ice Bank device, one must first know how this equipment works. The ice bank device is a set of evaporator plates that are placed vertically in the water tank, the cooling arteries pass through the heat exchange plates, absorb the heat of the water from outside the evaporator and cool the water to the freezing point.

Cold and freezing is stored statically in the water tank, so the water temperature in the water tank is very low. The ice bank device freezes the water plates inside the tank at night, which has a low energy cost. During the day when electricity is more expensive, the cooling system motor is turned off and uses the stored capacity to meet the cooling load needs.

Performance and benefits of the Ice Bank device

The idea behind the ice bank machine is very simple: during off-peak hours, when electricity rates are lower, the cooler turns on. The water inside the ice bank freezes and turns into ice. This process is called thermal storage. During the day (peak hours) the cooler is turned off to turn the ice into ice water. This ice can then be used for cooling.

This simple but efficient method of cooling is often used in pharmaceutical industries, food processing companies, dairy industries, etc. Although its function and principle are very simple, the Ice Bank device has many advantages:

The lowest possible installation cost

The lowest amount of energy consumption and maximum efficiency and work efficiency

Eco-friendly

Saving energy costs

Easy maintenance

Comfortable and easy operation

No need for ducting: installation costs are reduced due to no need for an additional duct distribution system.

No need to connect to the ceiling or need to install a chimney: installation on the floor and does not require options such as ceiling outlet.

No need for complicated wiring and power supply.

Ease of use with a strong structure, so it has a longer useful life.

The industrial building is easily cooled with controlled temperature. Another advantage of the Ice Bank is that it is possible to keep open surfaces such as factories and large companies cool with this device, especially in the hot seasons of the year. Naturally, the right temperature for the employees will give them more comfort and following the comfort of the employees, more productivity will be obtained.

Ice bank device and cost management of drug production

One of the most important challenges in the pharmaceutical industry is the discussion of production and management costs. The cost of drug development and production is high, so savings should be made wherever possible. Energy efficiency and precise water and temperature control processes dramatically reduce the operating costs of any system.

The Ice Bank device is specially designed to reduce water consumption and save energy. This device has the feature of consuming less energy while providing more efficiency. Ice Bank has responded to this need of drug production industries by increasing energy efficiency and minimizing operating costs by using intelligent control systems. Also, the ice bank controls and maintains the same temperature by constantly adjusting the air in the entire facility. Not only does indoor air recirculation provide a uniform temperature, but it also saves a lot on energy bills.

Quality control with ice bank device in drug production industries

Quality control for pharmaceutical products first begins with the accurate control of temperature, humidity and circulating air quality. For this reason, pharmaceutical companies are increasingly choosing the Ice Bank device for uniform air movement, heating control, cooling and refrigeration solutions. Ice Bank systems have a high standard of quality and can easily be combined with any working environment conditions and maintain the quality of products.

The importance of temperature control in drug manufacturing industries

From laboratories to manufacturing facilities, pharmaceuticals require precise control of humidity and temperature to maintain product uniformity and integrity. Humidity and temperature are key factors, but contamination of drugs should also be avoided, so air pressure and direction of air flow are critical for stability and non-penetration and proliferation of contaminating microorganisms in clinical environments.

For example, if vaccines are improperly stored at different temperatures, they will deteriorate due to temperature fluctuations. Contaminated vaccines are at best no longer effective, at worst they lead to serious complications when used for vaccination. Since patient safety is priceless, the ice bank device can be very effective due to its homogeneous temperature regulation.

Ice bank device for drug storage

Drug warehouse heating and cooling is very important for any warehouse that stores pharmaceutical goods. To prevent the quality and efficiency of the product from decreasing, the product must be kept within a certain temperature range. Extreme temperature in the medicine storage area can cause many problems.

The ice bank device is ideally used for the storage of reagents, vaccines and other biopharmaceutical products. Its temperature control system is very accurate and this is the most important factor to maintain the durability of the product. This device provides an ideal cold storage environment with no fluctuation.

Applications of ice bank device in drug production industries

Ice bank device is necessary for process control and environmental management in drug production and storage due to the high value of pharmaceutical raw materials, intermediate materials and final products. This device plays a vital role in the pharmaceutical industry with very precise temperature control and high reliability.

Most of the pharmaceutical products fall into a category that says “do not store above 25°C”, the Ice Bank device ensures that the pharmaceutical products are kept at the exact and desired temperature.

In drug production industries, since the storage of raw materials for drug production, an ice bank device is needed until the drug reaches the hands of drug wholesalers, this device is also effective.

Temperature compliance in the pharmaceutical industry is regulated by two criteria:

The average kinetic temperature in a seven-day period should not exceed 25 degrees Celsius.

The absolute maximum temperature should never exceed 30 degrees Celsius.

Most pharmaceutical warehouses use an ice bank device to keep products cool because other refrigeration devices are too expensive.

The ice bank device can maintain compliance with pharmaceutical industry standards over long periods of time at appropriate temperatures.

By using the ice bank device, it is possible to ensure the complete compliance of the desired temperature with the drugs.

Temperature control of the molding process when making gelatin for capsules.

Cooling cream components after heating and before mixing.

Heating and cooling during sterilization of liquid pharmaceuticals.

Water used in the wet granulation process to form tablets.

Cooling ointments before pouring into tubes and packaging.

The ice bank device plays an important role in every medical center. They are used to aid in the proper storage of vaccines, drugs, and biomedically valuable materials. This has a positive effect not only on healthcare centers, but also on laboratories. For many, the most important role of the ice bank device is to provide a safe storage of the vaccine by maintaining the “cold chain”.

Cold chain management in drug production industries

A “cold chain” is a set of temperature-controlled environments that help store, manage, and transport vaccines and drugs. It is important to maintain the quality of these products from production to transportation, distribution, storage and retail. This process in the pharmaceutical manufacturing industry usually starts with manufacturing and supply chain processes, controlled by the manufacturer’s temperature. Then he made sure that the proper temperature of the medicine is maintained and sent to the distributor. Finally, it is provided to patients in a pharmacy or healthcare facility.

The most common way manufacturers and distributors maintain the proper temperature during the handling process is through the use of refrigerated trucks and airplanes. In addition, manufacturers often ship their products inside insulated boxes. Maintaining a cold chain is very important because if drugs and vaccines are exposed to temperatures that are too high or too low, their potency decreases. Unfortunately, this lost power cannot be recovered. Therefore, if a vaccine or drug loses its potency, it cannot be used.

In the pharmaceutical industry, almost all drug manufacturers use cooling equipment as part of their production processes. These cooling equipment are used for critical applications such as research and development, pharmaceutical processing, cream and ointment cooling, liquid sterilization, tablet forming, packaging, and more. The Ice Bank device is used to meet the unique needs of the pharmaceutical and biotechnology industries, so you can easily focus only on treatment with this device.

References